Advertisements

Advertisements

प्रश्न

What is compaction in powder metallurgy?

उत्तर

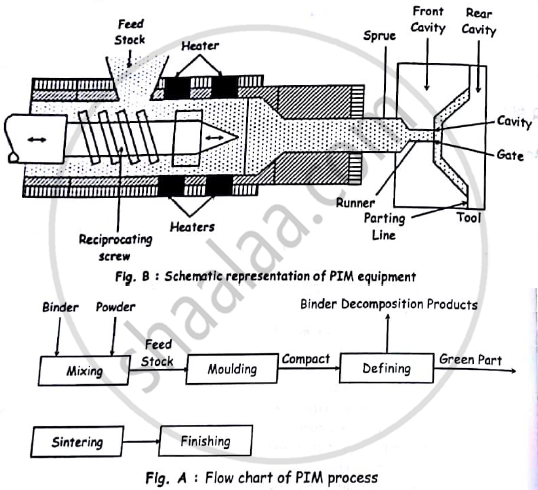

Explain powder injection moulding method with suitable diagram.

Compacting is the operation of obtaining object produced by the compression of a metal powder generally while confined in a die.

- Compaction is done without the application of heat.

- Loose powders are converted into required shape with sufficient strength to withstand ejection from tools and sintering process.

- In case like cemented carbide,hot compaction is done followed by sintering.

- Methods of compacting

a) Cold pressing.

b) Powder injection moulding.

c) Hot compaction.

a) Cold pressing

The powder with lubricant or binder and compacted in rigid dies by axially loaded punch.

b) Powder injection moulding

The powder is mixed with 30-40% binder and moulding is done by injection into mould by screw.

c) Hot compaction

Hot compaction mechanism is activated by higher processing temperatures and external pressure.

• The hot compaction include Axial & Isotactic hot pressing,hot forging,hot extrusion etc.

• The compact obtained by any above processes is known as green compact & further sintered.

Powder Injection Moulding

• The powder is mixed with 30-40% binder.

• It is injected into mould by screw.

• Mould is cooled and debinding is done.

• This method gives good stability and green strength of moulded prodicts

• User:This process creates very complex shapes from cemented carbides,tungsten alloys ceramics etc.

Powder Injection Moulding