Advertisements

Advertisements

प्रश्न

Write a note on sandwich panel type layered composites.

उत्तर

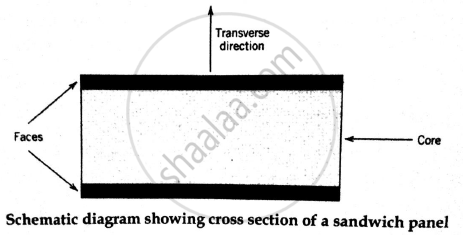

Sandwich Panels: Sandwich panels are designed to be light-weight beams or panels having relative high stiffness and strengths. A sandwich panel consists of two outer sheets or faces that are separated by and adhesively binded to a thicker core.Faces are made of a relatively stiff and strong material, typically aluminium alloys, fiber-reinforced plastics,titanium, steel or plywood.

Functions:

i)They impart high stiffness and strength to the structure.

ii)They must be thick enough to withstand tensile and compressive stresses that result from loading.The core material is light-weight has a low modulus of elasticity. Typical “core” materials include synthetic rubbers,formed polymers,balsa wood and inorganic cements.

Core servers the following two structural functions:

i)It separates the “faces” and provides continuous support fit the faces.

ii)They resist any deformations perpendicular to the face plane.

iii)It provides a certain degree of shear rigidity along the planes which are perpendicular to the “faces”.Another popular core consists of a “honeycomb” structure thin foils that have been formed into interlocking hexagonal cells,with axes oriented perpendicular to the face plane.

The honeycomb material is normally either an aluminium alloy or aramid polymer. Strength and stiffness of honeycomb structures depend on cell size, cell wall thickness, and the material from which the honeycomb is made.

Sandwich panels are used in a wide variety of applications including roofs, floors, and walls of buildings, and in aeroplanes and aircraft (i.e for wings, fuselage and tailplane skins.)